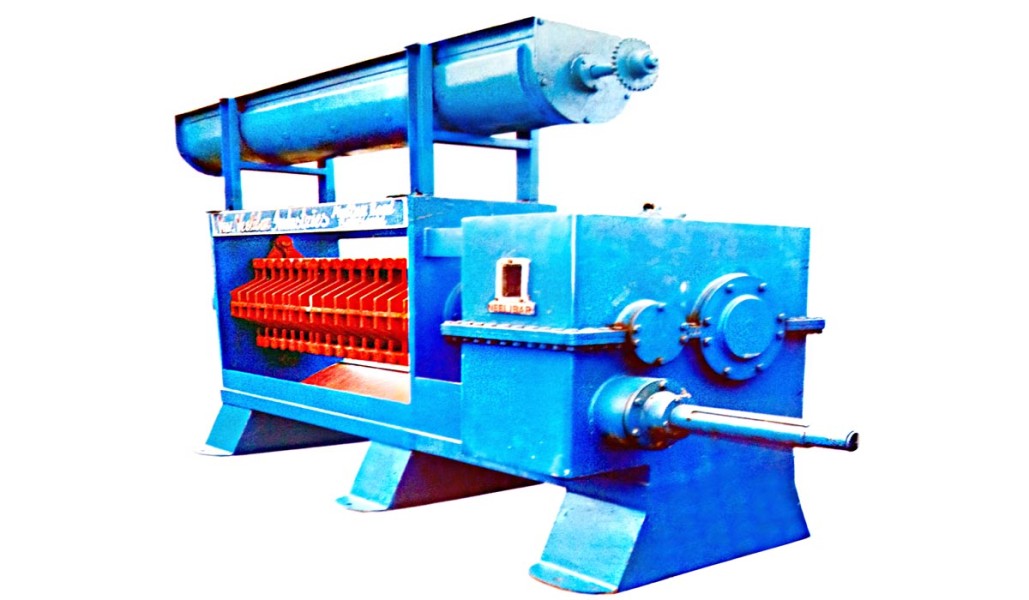

Oil Seed Screw Pres

Feeding: The oilseeds are first cleaned and prepared by removing any impurities, such as dirt or stones. They are then fed into the screw press hopper. Pressing: Inside the screw press chamber, the seeds are gradually pushed forward by a rotating screw. As the seeds move through the chamber, they experience increasing pressure and heat due to the compression caused by the screw. This pressure and heat cause the oil to be released from the seeds. Separation: The oil that is released from the seeds is separated from the solid seed residue (called the cake) as it exits the press. The oil typically flows through a screen or filter, while the cake is expelled from the press. Collection: The extracted oil is collected in a container, while the cake can be used as animal feed or further processed for various purposes. The effectiveness of a small oil seed screw press depends on factors such as the type of seeds being processed, the moisture content of the seeds, the pressure applied, and the temperature inside the press. It's important to adjust these parameters to optimize oil extraction efficiency and quality. Small oil seed screw presses are commonly used by small-scale farmers and artisanal oil producers to produce vegetable oils for cooking, biofuels, and other applications. They are relatively simple machines, easy to operate, and require minimal maintenance. However, they may have limited capacity compared to larger industrial oil extraction equipment.